Leading the industry with high quality finishes and technology

What is the difference between PVD, Powder Coat, Laquer and Chrome finish technologies?

The Kitchen and Bath plumbing fixture industry relies heavily on 4 main finish types to achieve the desired look for consumers and designers alike. PVD, Laquer, Polished Chrome and Powder Coat methods each contain pros and cons with respect to appearance and durability. In the overview below, each one of these finish types are explained in a bit more detail when used for decorative plumbing:

- PVD - Most durable of the four, and most commonly used for metallic surface finishes. PVD Surfaces are exceptionally resistant to scratching, cleaning agents and salty sea air

- Laquer - Lacquer provides an bold and intense surface finish that appears deep and authentic. It can be glossy or flat. Laquer is durable, but less so than Chrome or PVD.

- Powder Coat - Commonly used for non-metallic surfaces and colours, Powder Coat finishes may have a slight texture in their appearance, and are reasonably resistant to chipping and abrasion.

- Polished Chrome - Polished Chrome is an electroplated finish most are familiar with, offering a brilliant mirror-like surface that is very durable.

To achieve the finish result that consumers demand across our expansive bath and kitchen collections, hansgrohe uses all of the finish technologies on some level. As PVD finishes tend to be the most versatile and durable, this technology makes up the majority of our high quality special finish products. Our organization continues to invest in this technology as it is one of the most durable surfaces used in a wide range of colours and textures.

What makes our PVD so durable?

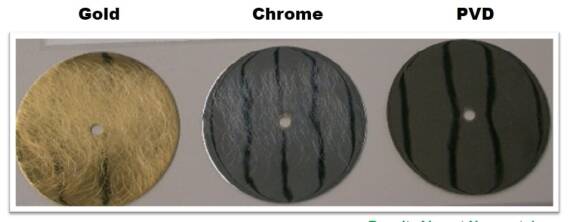

Our PVD process ensures that your purchase maintains its exquisite colour and scratch-resistant design. The picture to the left is a result of our hansgrohe PVD Scratch Test; we used 3M Scotch-Brite Sponges™ (300 gram pressure) on our finishes. During our test we cycled the sponges 500 times; the result was an intact PVD surface when compared to industry standard finishes such as Polished Chrome and Polished Brass.

Physical Vapour Deposition at hansgrohe

With nearly two decades of experience in individualization and custom-made products, we have continued to invest in increasing our finishes production and individualisation capabilities. We have expanded our in-house PVD chambers, with continued investing in our finishing capabilities to make custom finishes increasingly available with shorter production lead times. Our broad scope of individualisation services with hansgrohe products provide a solution for each customer.

Our PVD coating is an automated and consistent process, promising the highest quality for all of our products. There is also a visual inspection of each product from qualified and trained employees to support the guarantee of the highest standard.

What is Physical Vapour Deposition?

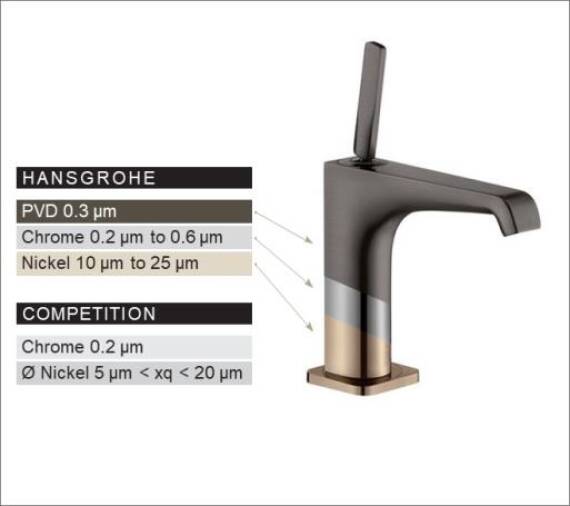

PVD is a vacuum coating process. Due to a moderate temperature and absence of wet chemistry there is a wide range of coating options for many materials such as pure metal, plastic and glass. Before production, products have to be cleaned in an industrial high-tech washing machine to eliminate remaining contaminations. After second control and wiping the parts by hand, they are ready to receive their special finish in the PVD chamber. During the process, the coating material is vaporized and rotated in the PVD chamber. The parts are rotated in a the chamber by a planetary gearset similar to an automatic transmission in a car. Simultaneously, special gasses are used in the chamber to evenly deposit the vaporized metal on the surface of our parts. Changing the composition of the gas mixture determines the colouring of the deposited layer which is 0.3 microns thick.

The outcome is a superbly robust, durable and stylish look that will stand the test of time. PVD finish options are found on a large portion of our collections so finding a finish option within your desired hansgrohe product is simple and easy.

Adding character to interior design

Trusted partners